<h1>Turbocharger In-situ Machining</h1>

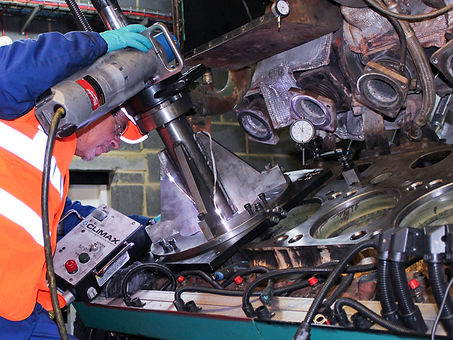

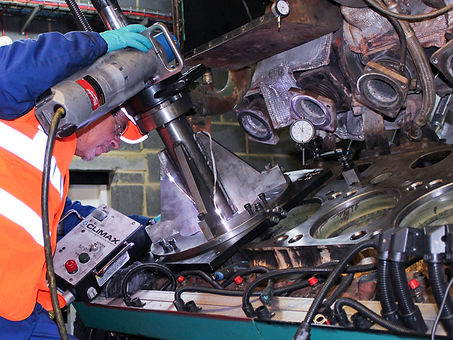

A marine turbocharger is very huge and also very expensive to buy a new one; therefore, the existing turbocharger should be properly maintained and repaired so that the life of the turbocharger increases as well as the efficiency of the turbocharger increases; otherwise, the expenses will eventually increase and the engine efficiency will also decrease if the turbocharger is not properly maintained. In-situ machining refers to the servicing or maintenance of a component that is difficult to bring to the workshop for repair and, in some cases, it is not financially viable to bring a component to the workshop for small overhauling and inspection purposes; therefore, in in-situ machining, service engineers come to the site i.e., onboard and perform the task. Since the marine turbocharger is so large, it cannot be moved to a repair shop for inspection and servicing every time. For this, there is in-situ machining, which is preferable if there are minor servicing changes, and inspection, which is very helpful because expert service engineers come onboard with proper machining tools and equipment and perform the inspection and overhauling process of the turbocharger. This has to be done very carefully and keeping the vessel at upright position so that there is very less listing of the vessel which can cause disturbance while maintenance and inspection work. Since the turbocharger is a very closed device, it must be dismantled for any inspection or service work. With in-situ machining, this can be done onboard, saving time and money that would otherwise be spent transferring the turbocharger to the in-shop repair. Major repairing of the turbocharger is not possible onboard, but inspection and overhauling of the essential components is possible, which will save a lot of time because inspection and overhauling in workshop will take a lot of time and the vessel will have to be out of service for a few days, which can have an economic impact. Nowadays, owing to advancements in technology, inspection and testing work is becoming easier, and this can be done in the case of a turbocharger. While substantial repairing is not feasible, the majority of component maintenance can be done with the aid of in-situ machining.

References:

1. <a href="https://www.quantiserv.com/in-situ-machining/

">quantiserv.com</a>

2.<a href="https://tsi.eu.com/?gclid=Cj0KCQiAjc2QBhDgARIsAMc3SqQssrQqrX2Jn7clTOW4QTHRSlDR6U24KLMelzitueK07m1T5e-STuIaAumFEALw_wcB">tsi.eu.com</a>

<h1>Turbocharger In-situ Machining</h1>

A marine turbocharger is very huge and also very expensive to buy a new one; therefore, the existing turbocharger should be properly maintained and repaired so that the life of the turbocharger increases as well as the efficiency of the turbocharger increases; otherwise, the expenses will eventually increase and the engine efficiency will also decrease if the turbocharger is not properly maintained. In-situ machining refers to the servicing or maintenance of a component that is difficult to bring to the workshop for repair and, in some cases, it is not financially viable to bring a component to the workshop for small overhauling and inspection purposes; therefore, in in-situ machining, service engineers come to the site i.e., onboard and perform the task. Since the marine turbocharger is so large, it cannot be moved to a repair shop for inspection and servicing every time. For this, there is in-situ machining, which is preferable if there are minor servicing changes, and inspection, which is very helpful because expert service engineers come onboard with proper machining tools and equipment and perform the inspection and overhauling process of the turbocharger. This has to be done very carefully and keeping the vessel at upright position so that there is very less listing of the vessel which can cause disturbance while maintenance and inspection work. Since the turbocharger is a very closed device, it must be dismantled for any inspection or service work. With in-situ machining, this can be done onboard, saving time and money that would otherwise be spent transferring the turbocharger to the in-shop repair. Major repairing of the turbocharger is not possible onboard, but inspection and overhauling of the essential components is possible, which will save a lot of time because inspection and overhauling in workshop will take a lot of time and the vessel will have to be out of service for a few days, which can have an economic impact. Nowadays, owing to advancements in technology, inspection and testing work is becoming easier, and this can be done in the case of a turbocharger. While substantial repairing is not feasible, the majority of component maintenance can be done with the aid of in-situ machining.

References:

1. <a href="https://www.quantiserv.com/in-situ-machining/

">quantiserv.com</a>

2.<a href="https://tsi.eu.com/?gclid=Cj0KCQiAjc2QBhDgARIsAMc3SqQssrQqrX2Jn7clTOW4QTHRSlDR6U24KLMelzitueK07m1T5e-STuIaAumFEALw_wcB">tsi.eu.com</a>

Turbocharger In-situ Machining

<h1>Turbocharger In-situ Machining</h1>

A marine turbocharger is very huge and also very expensive to buy a new one; therefore, the existing turbocharger should be properly maintained and repaired so that the life of the turbocharger increases as well as the efficiency of the turbocharger increases; otherwise, the expenses will eventually increase and the engine efficiency will also decrease if the turbocharger is not properly maintained. In-situ machining refers to the servicing or maintenance of a component that is difficult to bring to the workshop for repair and, in some cases, it is not financially viable to bring a component to the workshop for small overhauling and inspection purposes; therefore, in in-situ machining, service engineers come to the site i.e., onboard and perform the task. Since the marine turbocharger is so large, it cannot be moved to a repair shop for inspection and servicing every time. For this, there is in-situ machining, which is preferable if there are minor servicing changes, and inspection, which is very helpful because expert service engineers come onboard with proper machining tools and equipment and perform the inspection and overhauling process of the turbocharger. This has to be done very carefully and keeping the vessel at upright position so that there is very less listing of the vessel which can cause disturbance while maintenance and inspection work. Since the turbocharger is a very closed device, it must be dismantled for any inspection or service work. With in-situ machining, this can be done onboard, saving time and money that would otherwise be spent transferring the turbocharger to the in-shop repair. Major repairing of the turbocharger is not possible onboard, but inspection and overhauling of the essential components is possible, which will save a lot of time because inspection and overhauling in workshop will take a lot of time and the vessel will have to be out of service for a few days, which can have an economic impact. Nowadays, owing to advancements in technology, inspection and testing work is becoming easier, and this can be done in the case of a turbocharger. While substantial repairing is not feasible, the majority of component maintenance can be done with the aid of in-situ machining.

References:

1. <a href="https://www.quantiserv.com/in-situ-machining/

">quantiserv.com</a>

2.<a href="https://tsi.eu.com/?gclid=Cj0KCQiAjc2QBhDgARIsAMc3SqQssrQqrX2Jn7clTOW4QTHRSlDR6U24KLMelzitueK07m1T5e-STuIaAumFEALw_wcB">tsi.eu.com</a>

<h1>Turbocharger In-situ Machining</h1>

A marine turbocharger is very huge and also very expensive to buy a new one; therefore, the existing turbocharger should be properly maintained and repaired so that the life of the turbocharger increases as well as the efficiency of the turbocharger increases; otherwise, the expenses will eventually increase and the engine efficiency will also decrease if the turbocharger is not properly maintained. In-situ machining refers to the servicing or maintenance of a component that is difficult to bring to the workshop for repair and, in some cases, it is not financially viable to bring a component to the workshop for small overhauling and inspection purposes; therefore, in in-situ machining, service engineers come to the site i.e., onboard and perform the task. Since the marine turbocharger is so large, it cannot be moved to a repair shop for inspection and servicing every time. For this, there is in-situ machining, which is preferable if there are minor servicing changes, and inspection, which is very helpful because expert service engineers come onboard with proper machining tools and equipment and perform the inspection and overhauling process of the turbocharger. This has to be done very carefully and keeping the vessel at upright position so that there is very less listing of the vessel which can cause disturbance while maintenance and inspection work. Since the turbocharger is a very closed device, it must be dismantled for any inspection or service work. With in-situ machining, this can be done onboard, saving time and money that would otherwise be spent transferring the turbocharger to the in-shop repair. Major repairing of the turbocharger is not possible onboard, but inspection and overhauling of the essential components is possible, which will save a lot of time because inspection and overhauling in workshop will take a lot of time and the vessel will have to be out of service for a few days, which can have an economic impact. Nowadays, owing to advancements in technology, inspection and testing work is becoming easier, and this can be done in the case of a turbocharger. While substantial repairing is not feasible, the majority of component maintenance can be done with the aid of in-situ machining.

References:

1. <a href="https://www.quantiserv.com/in-situ-machining/

">quantiserv.com</a>

2.<a href="https://tsi.eu.com/?gclid=Cj0KCQiAjc2QBhDgARIsAMc3SqQssrQqrX2Jn7clTOW4QTHRSlDR6U24KLMelzitueK07m1T5e-STuIaAumFEALw_wcB">tsi.eu.com</a>